Polypropylene

Polypropylene is a tough, rigid and crystalline thermoplastic produced from propene (or propylene) monomer. It is a linear hydrocarbon resin. The chemical formula of polypropylene is (C3H6)n. PP is among the cheapest plastics available today.

What is Polypropylene and What It’s Used for?

Polypropylene is a tough, rigid and crystalline thermoplastic produced from propene (or propylene) monomer. It is a linear hydrocarbon resin. The chemical formula of polypropylene is (C3H6)n. PP is among the cheapest plastics available today.

PP belongs to polyolefin family of polymers and is one of the top three widely used polymers today. Polypropylene has applications both as a plastic and a fiber in:

- Automotive Industry

- Industrial Applications

- Consumer Goods, and

- Furniture Market

It has the lowest density among commodity plastics.

Some of the key suppliers of polypropylene are:

- GAPEX, ACCUTECH, POLYFORT, Fiberfil, FERREX and more

- Daplen, Bormed, Fibremod and more

- ExxonMobil, Achieve

- Adstif, Circulen, Hifax, Hostacom, Moplen and more

- SABIC PP, SABIC Vestolen, LNP THERMOCOMP and more

- ESD C, ESD A, RTP 100, RTP 101 to 109 and more

How to Produce Polypropylene?

These days, polypropylene is made from polymerization of propene monomer (an unsaturated organic compound – chemical formula C3H6) by:

- Ziegler-Natta polymerization or

- Metallocene catalysis polymerization

Upon polymerization, PP can form three basic chain structures depending on the position of the methyl groups:- Atactic (aPP) – Irregular methyl group (CH3) arrangement

- Isotactic (iPP) – Methyl groups (CH3) arranged on one side of the carbon chain

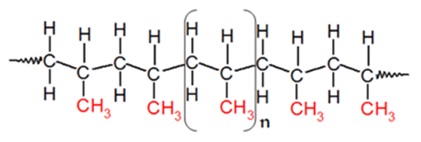

- Syndiotactic (sPP) – Alternating methyl group (CH3) arrangementWhat is Polypropylene and What It’s Used for?Polypropylene is a tough, rigid and crystalline thermoplastic produced from propene (or propylene) monomer. It is a linear hydrocarbon resin. The chemical formula of polypropylene is (C3H6)n. PP is among the cheapest plastics available today.Molecular Structure of Polypropylene

Molecular Structure of Polypropylene

PP belongs to polyolefin family of polymers and is one of the top three widely used polymers today. Polypropylene has applications both as a plastic and a fiber in:

Automotive Industry

Industrial Applications

Consumer Goods, and

Furniture MarketIt has the lowest density among commodity plastics.

Some of the key suppliers of polypropylene are:

A. Schulman – GAPEX®, ACCUTECH™, POLYFORT®, Fiberfil®, FERREX® and more

Borealis – Daplen™, Bormed™, Fibremod™ and more

ExxonMobil Chemical – ExxonMobil™, Achieve™

LyondellBasell – Adstif, Circulen, Hifax, Hostacom, Moplen and more

SABIC – SABIC® PP, SABIC® Vestolen, LNP™ THERMOCOMP™ and more

RTP Company – ESD C, ESD A, RTP 100, RTP 101 to 109 and moreHow to Produce Polypropylene?

These days, polypropylene is made from polymerization of propene monomer (an unsaturated organic compound – chemical formula C3H6) by:

Ziegler-Natta polymerization or

Metallocene catalysis polymerizationStructure of PP Monomer

Structure of PP Monomer

C3H6 Ziegler-Natta Polymerization

Arrow

Or Metallocene Catalysis Structure of Polypropylene

Structure of Polypropylene

(C3H6)nUpon polymerization, PP can form three basic chain structures depending on the position of the methyl groups:

Atactic (aPP) – Irregular methyl group (CH3) arrangement

Isotactic (iPP) – Methyl groups (CH3) arranged on one side of the carbon chain

Syndiotactic (sPP) – Alternating methyl group (CH3) arrangementTypes of Polypropylene

Facts to Know Polypropylene was first polymerized by German chemist named Karl Rehn and an Italian chemist named Giulio Natta to a crystalline isotactic polymer in 1954. This discovery soon led to a large-scale production of polypropylene starting in 1957 by the Italian firm Montecatini.

Syndiotactic polypropylene was also first synthesized by Natta and his coworkers.

Types of Polypropylene & their Benefits

Homopolymers and Copolymers are the two major types of polypropylene available in the market.

Polypropylene Homopolymer is the most widely utilized general-purpose grade. It contains only propylene monomer in a semi-crystalline solid form. Main applications include packaging, textiles, healthcare, pipes, automotive and electrical applications.

Polypropylene Copolymer family is further divided into random copolymers and block copolymers produced by polymerizing of propene and ethane:

Polypropylene Random Copolymer is produced by polymerizing together ethene and propene. It features Ethene units, usually up to 6% by mass, incorporated randomly in the polypropylene chains. These polymers are flexible and optically clear making them suitable of applications requiring transparency and for products requiring an excellent appearance.

While in Polypropylene Block Copolymer, ethene content is larger (between 5 and 15%). It has co-monomer units arranged in regular pattern (or blocks). The regular pattern hence makes thermoplastic tougher and less brittle than the random co-polymer. These polymers are suitable for applications requiring high strength, such as industrial usages.

Polypropylene, Impact Copolymer – Propylene Homopolymer containing a co-mixed Propylene Random Copolymer phase which has an ethylene content of 45-65% is referred to PP impact copolymer. It is useful in parts which require good impact resistance. Impact copolymers are mainly used in packaging, houseware, film, and pipe applications, as well as in the automotive and electrical segments.

Expanded Polypropylene – It is a closed-cell bead foam with ultra-low density. EPP is used to produce three-dimensional polymer foam products. EPP bead foam has higher strength to weight ratio, excellent impact resistance, thermal insulation, and chemical and water resistance. EPP is used in various applications ranging from automobiles to packaging, from construction products to consumer goods and more.

Polypropylene Terpolymer – It is composed by propylene segments joined by monomers ethylene and butane (co-monomer) which appear randomly throughout the polymer chain. PP terpolymer has better transparency than PP homo. Also, the incorporation of co-monomers reduces crystalline uniformity in the polymer making it suitable for sealing film applications.

Polypropylene, High Melt Strength (HMS PP)– It is a long chain branched material, which combines both high melt strength and extensibility in the melt phase. PP HMS grades have a wide mechanical property range, high heat stability, good chemical resistance. HMS PP is widely used to produce soft, low density foams for food packaging applications as well as used in automotive and construction industries.